|

Learn To Finish Drywall From a Pro!

You wont find this information anywhere else!

Your Program Includes:

A 226-page eBook packed full of drywall trade secrets: "The Trade Secrets to EASIER Taping, Finishing and Texturing"

PLUS

Bonus Guide #1: "Sagging Ceilings - Can You Avoid the Tear-Out?"

Bonus Guide #2: "The Mud Swirl." A short 6-page how-to guide for this popular type of texture.

Bonus #3: Unlimited FREE Access to 17 On-The-Job Training Videos!

|

Sheetrock and Repair Tips for Sanding Drywall

The following sheetrock and repair tips include a dependable step-by-step routine for sanding any drywall project, along with a link to some important painting tips and other information that you won't find anywhere else! Even if you decide to use the sanding machines that are available, youll still need this step-by-step routine for correcting every flaw - BEFORE you start painting.

First of all, theres no need to sand drywall two different times with two different types of sandpaper, although some authors recommend this approach.

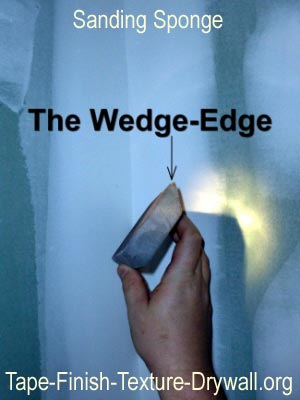

This machine does all the work and sucks up the dust at the same time! What more could you ask for? The only thing that it doesnt do are the tight little intricate areas (like inside corners) which are done by hand with a sanding sponge. Another dust-free alternative:  Sheetrock and Repair Tips# 2: The hand-sander shown above hooks up to a vac and requires the use of sanding screen. You can also find sanding poles that are designed the same way. With a decent shop vac, you wont create any dust!  Sheetrock and Repair Tips #3: Remember, few parts of a drywall job are actually flat. Many beginners will attempt to sand everything flat by sanding their recessed joints all the way down to the level of the factory recess. Read Chapter 9 of the Trade Secrets Course if you dont already understand why this is a waste of time.  You will need the following:

|